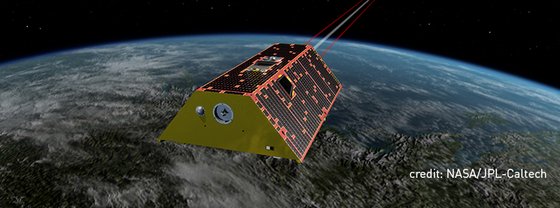

From Gravity to Water on Earth – with GRACE

German Space Agency at German Aerospace Center (DLR) contracts SpaceTech for laser instrument development and launcher procurement for German-American…

Interferometer for Aeolus-2 mission

SpaceTech has been contracted by ESA for the pre-development of a Double field compensated Michelson Interferometer (DMI) and a Fizeau interferometer…

2023 – a year of steady growth at SpaceTech

Another year has almost passed. Time to thank you again for all the good work we did together, for the ideas, the fruitful discussions, the fairness,…

VfB Volleyball Erfolg in der SPACETECH ARENA

Der VfB spielt sich warm in der SPACETECH ARENA – mit dem 3:0 Bundesligasieg gegen Düren am 08.12.23 konnte das Team bereits den dritten Heimsieg der…

Euclid delivers first pictures

Euclid is an ESA mission to map the geometry of the Universe and better understand the mysterious dark matter and dark energy...

SPACETECH ARENA

Heimspielstätte bekommt neuen Namen – VfB Friedrichshafen schlägt ab sofort in der SPACETECH ARENA auf...

Erfolg für das STI Laufteam beim ZF-Firmenlauf 2023

Das stetig wachsende SpaceTech Laufteam startete wieder beim ZF Firmenlauf in Friedrichshafen mit großartigen Ergebnissen...

Euclid mission getting ready for launch – with STI sunshield

The Euclid mission, part of ESA's Cosmic Vision program, is getting ready for its launch.

EIVE in orbit

EIVE launch successful - Congratulations to the whole EIVE satellite team!